INTRODUCTION

India incurs post-harvest losses of fruits and vegetable worth Rs. 2 lakh crore per year, due to lack of proper storage and processing facilities, according to a study in the Economic times (2014). Tomato is a major vegetable crop that is used widely throughout the different strata’s of the population over the last century. Tomato is grown in an area of 8.65 lakh hectares with an average production of 168.26 lakh tones in India.[1] Tomatoes spend so much time on shelves and in refrigerators that an estimated 20% are lost to spoilage. From the moment produce is harvested the clock starts ticking and produce decay begins. The main factors that affect shelf life of produce include improper handling, inadequate humidity, temperature abuse, and ethylene exposure.[2,3] Many tomatoes which are grown for fresh consumption are picked when still firm and green, stored at low temperature and exposed to exogenous ethylene to induce color, and ripeness before reaching the supermarket shelf. Although this process is effective in limiting postharvest losses, these chemicals negatively affect tomato flavor, aroma, and texture.[4] The common use of ethylene inhibitors affecting ripening has similar negative impacts on flavor. Thus, in the present study, in an attempt to prevent the use of chemicals for increasing the shelf life and decreasing post-harvest losses as well as flavor loss in tomato, Aloe vera herbal coatings have been used in different combinations of temperature, pH, and plant extracts.

A. vera is widely used as an antimicrobial agent. They protect the quality losses during ambient storage.[5] The quality is depended on the plant variety, stage of fruits, and presents and past condition of the fruit.[6,7] A. vera is used in medicinal and therapeutic properties because it is a tropical and subtropical plant.[8] A. vera helps in protection from microorganisms and is also a herbal remedy for regeneration and rejuvenation of human skin.[9] A. vera gel (AG) is also used in the food industry such as in drinks, beverages, and ice creams.[10]

MATERIALS AND METHODS

AG Preparation

AG matrix was separated from the outer layer of leave, and this colorless hydroparenchyma was ground in homogenizer and the crude AG was prepared. This gel was diluted with distill water and filtered to remove the fibers. The liquid obtained constituted fresh AG. The gel matrix was pasteurized at 70°C for 45 min. After pasteurized, the gel was cooled down to ambient temperature. Salicylic acid (2.5 g L-1) (SA), citric acid (4.5 g L-1) (CA), and neem extract (10-20%) were added in 40% AG, and the pH was maintained at 4. The coating efficiency was improved using 0.1% commercial gelling agent for coating agent, and the fruit and vegetable sample was coated with coating agent.[11] After coating, the fruit was weighed and stored under different condition.

Application of Herbal Coating

The fresh fruits were dipped in coating solution at room temperature for 15 min. They were allowed to dry at room temperature to allow a thin-film layer to be formed on the fruits. Six tomatoes were used for each parameter testing. Fruits were then weighed and stored at 25°C or 4°C. Tomatoes without coating were stored under same conditions as those for coated fruits.

Parameters Analyzed

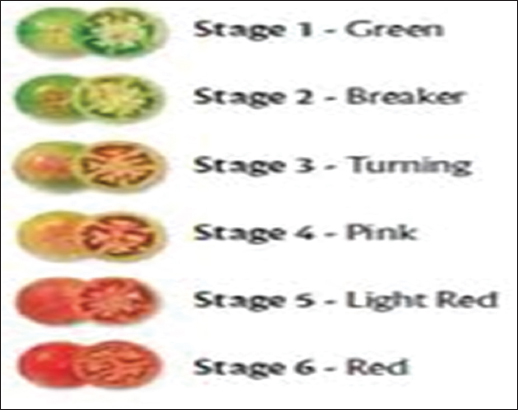

Various parameters were analyzed at fixed intervals. The parameters analyzed included physiological loss in fresh weight (PLW),[12] change in peel color, and sensory analysis of fruit quality. Visual analysis of the fruit was done for the change in fruit weight and peel color rating.

Peel color rating is done on the basis of 6-point score scale as given in Figure 1.

Figure 1: 6-point score of peel color rating scale

Sensory Analysis

Sensory analysis was carried out by six selected panelists. The fruits were randomly selected from each batch was evaluated visually in terms of peel color, texture, flavor, and marketability. They rated each of the variant on the basis of 9-point Hedonic score scale.

(1 = Dislike extremely, 2 = Dislike very much, 3 = Dislike moderately, 4 = Dislike slightly, 5 = Neither like nor dislike, 6 = Like slightly, 7 = Like moderately, 8 = Like very much, 9 = Like extremely).

RESULT

The effect of different formulations of A. vera coating was observed for as long as 36–40 days. PLW during storage was found to be significantly different among the tomatoes treated with the different coatings and control at the end of 20 days storage.

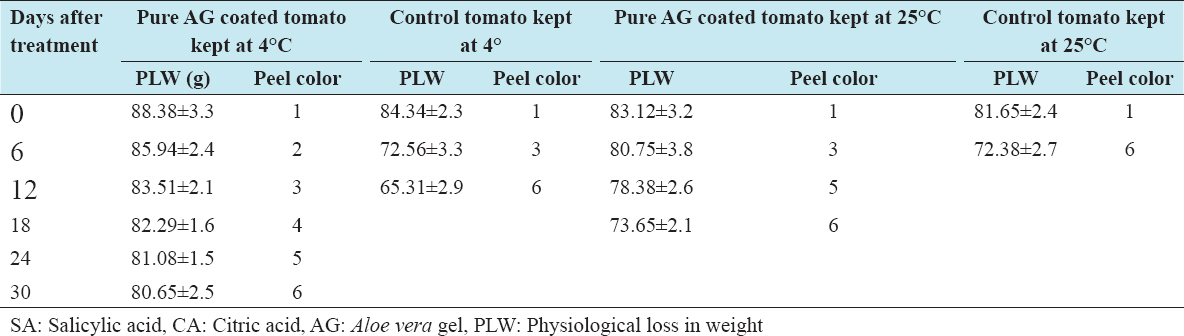

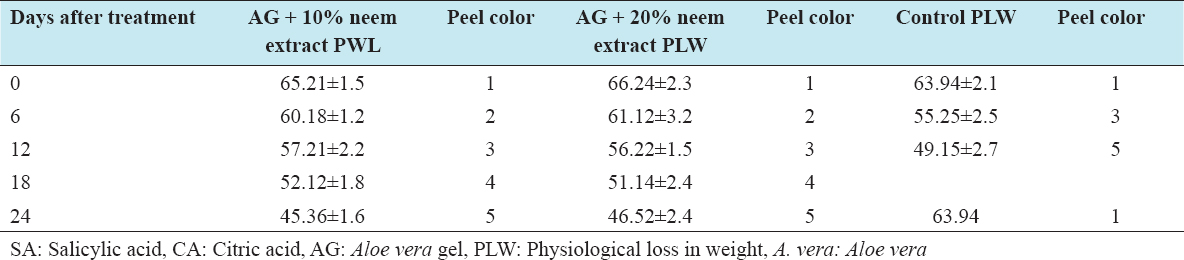

Change in peel color rating is observed in tomatoes during 36–40 days storage. It was observed that when pure AG was coated on the tomatoes, the result was astonishing. Since the control tomatoes showed ripening on the 6th day and were red and showed 6 rating of peel color. They also became soft and unmarketable. In comparison, the AG coated tomatoes showed ripening at 18 days when kept at 25°C and ripening at 30 days when stored at 4°C. Thus, it is observed that the AG coating not only prevents fungal growth on the tomatoes, it prevents ripening, thus increasing the shelf life and marketability of the tomatoes by 20–24 days. The PLW was also less in pure AG coated as compared to the control tomatoes [Table 1].

Table 1: PLW (g) and peel color rating with coating of AG

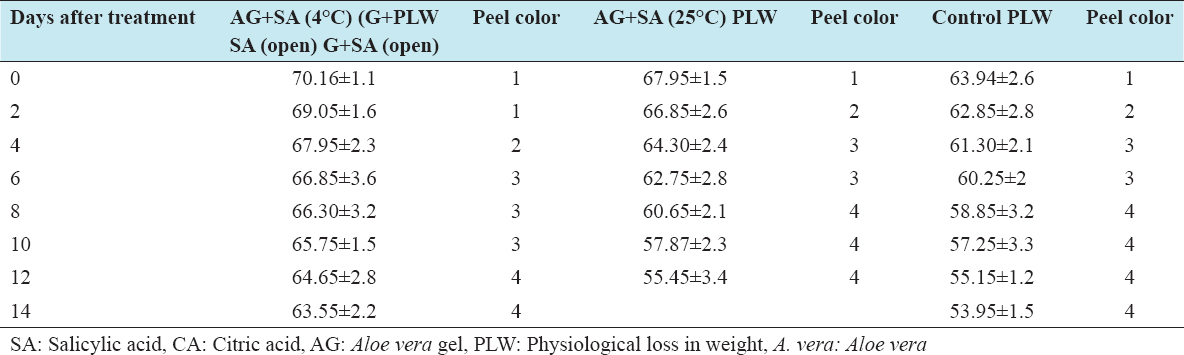

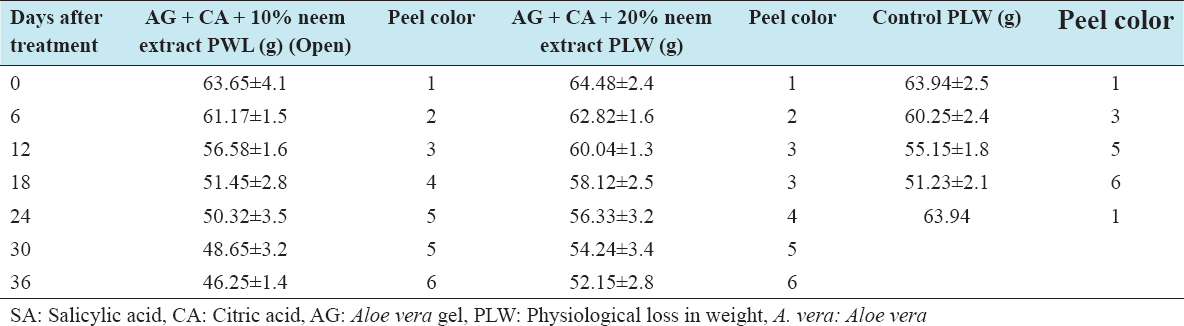

The coating of AG + SA formulations [Table 2] at different concentrations did not give good results as compared to only pure AG coating. Formulations having different concentrations of AG, CA, SA, and neem extract were tried for the study. Neem extract when used at 20% along with AG and CA gave enhanced results [Table 4]. An increase in shelf life and peel color rating was seen from 18 days in 4°C of the control tomatoes to 36 days for the tomatoes coated with neem extract + CA + AG.

Table 2: PLW (g) and peel color rating with coating of SA + 40% A. vera (4°C) and (25°C)

Table 3: PLW (g) and Peel color rating with coating of neem extract + 40% A. vera (4°C)

Table 4: PLW (g) and peel color rating with coating of neem extract + 40% A. vera+CA (4°C)

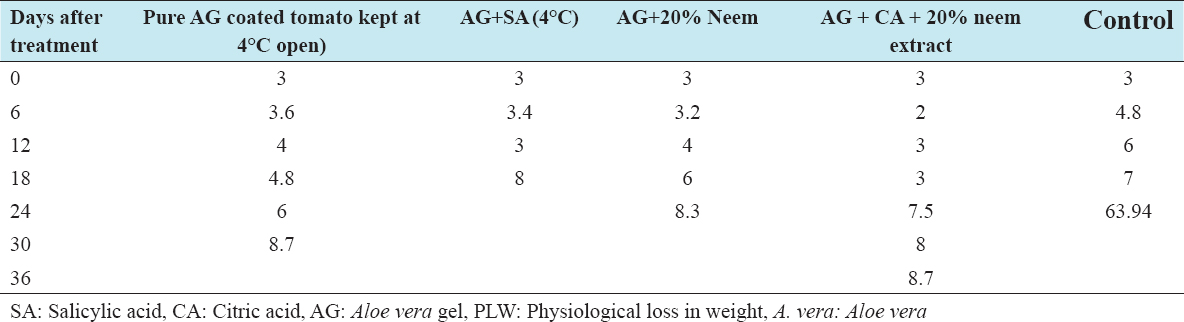

Color, firmness, taste, and marketability the major sensory attributes were scored by selected panel members. On the 30th day, overall score of 8.7 and 8.0 was obtained for pure AG and AG + CA + neem, respectively and control was already diseased and not eatable on 18 days. AG + CA + neem gave an overall score of 8.7 even on the 36th day after treatment [Table 5].

Table 5: Sensory + visual analysis of tomatoes on the basis of 1-9 scale

Statistical Analysis

Mean PLW, peel color, and sensory and visual analysis of all samples were calculated after calculation of standard deviation. Using one-way ANOVA, P values of PLW (0.025 < 0.05) and peel color change (0.001 < 0.05) indicated that there was a significant difference between the shelf life of tomatoes when AG was used as an edible coating at 4°C. Standard deviation in above parameters is shown in tables for PLW. The peel color and sensory and visual analysis are the mean of replicates for every test.

DISCUSSION

There is a high production of tomato fruits during the harvest time, but post-harvest processing and preservation techniques are inefficient. Therefore, fruits spoil very early due to lack of appropriate systems of preservation and processing.[13] Edible coatings can provide an additional protective coating for fresh products and can also give the same effect as modified atmosphere storage.[14,15] A. vera is a tropical or subtropical plant containing two major liquid sources, yellow latex (exudates) and clear gel (mucilage). Yellow latex is mainly composed of aloin, aloe-emodin, and phenols. The mucilaginous jelly from the parenchymal cells of the plant is the AG.

In the present work, AG with CA and neem extract was used to study their effect on increasing the shelf life by spraying the above mixture on the tomatoes [Table 3]. Control showed complete ripening red in color, soft, and marketable at 12–18 days at different temperatures, AG + SA coated showed similar to control. AG + CA + neem showed ripening and firmness and good taste on the 36th day also. Pure AG coated tomatoes were intermediate between the control and neem and CA coated. They gave a marketability range of 24 days.

Pure AG and AG with CA coated tomatoes when maintained at pH 4, at 25°C showed delayed ripening and extended the shelf life up to 16–18 days, whereas control got deteriorated within 5 days.

The results have proved the ability of different formulations of A. vera in extending the shelf life of tomatoes. Tomatoes stored with A. vera formulation having both neem extract and CA showed the maximum control on ripening in tomatoes. Pure AG has extended the shelf life up to 30 days. Different concentrations of pure A. vera have shown appreciating results. 40% AG with CA gave the best results in comparison to 20%, 40%, 60%, and 80% AG coated tomatoes.

Composed of polysaccharides, the AG appears to act as a natural barrier to moisture and oxygen which can speed up food deterioration. It can also enhance food safety. AG appears to contain various antibiotic and antifungal compounds that can potentially delay or inhibit microorganisms that are responsible for foodborne illness in humans as well as food spoilage.[16]

In a similar study by Chrysargyris et al.,[17] tomato fruit was coated with 0%, 5%, 10%, 15%, and 20% AG and fruit quality maintenance was examined up to 14 days at 11°C and 90% relative humidity. Results showed that 10% and 15% A. vera coating reduced fruit ethylene production. Chauhan et al., 2015[18] gave experimental results showing tomato fruits showed a shelf life of 9 and 12 days, respectively, for shellac alone and shellac with AG coated fruits against the shelf life of 6 days for uncoated fruits at ambient temperature (26-32°C). The coating made up of shellac alone gave lesser shelf life due to excessive ethanol formation caused by anaerobiosis.

AG-based edible coatings have been shown to prevent loss of moisture and firmness, control respiratory rate and maturation development, delay oxidative browning, and reduce microorganism proliferation in fruits such as sweet cherry, table grapes, and nectarines.[19]

Mean fresh weight, firmness, and PG activity of all three samples are 26.43 g, 3.78 kg/cm2, and 67.69 mg glucose equivalent/g fresh weight/hr, respectively. Using one-way ANOVA, P values of fresh weight remains (0.029 < 0.05), firmness (0.001 < 0.05), and PG activity (0.13 < 0.05) indicated that there was a significant difference between PG activity of all treatments applied to tomato fruits.[20]

A. vera with CA and neem extract can thus play a significant role in extension of shelf life of tomatoes as less microbial infection is observed comparative to other formulation of A. vera. A. vera with CA and neem extract improved the quality, firmness, color, marketability, and sensory characteristics of tomato. Application of an edible coating can thus become a technique that can be used to increase vegetable and fruit storability/shelf life.